|

|

|

|

|

SILO

UNLOADERS - VALMETAL

|

| |

|

|

|

Valmetal

970 Ring Drive Silo Unloaders |

-

The drive ring's large diameter along with wall

to wall suspension arms guarantee the perfect equilibrium

of the machine without counter weight

- The deep-sided fiberglass chute features a smooth

and slippery finish inside

- Three 5/16" galvanized aircraft type cable

support the unloader from 3 widely spaced points

which results in a level cut from top to bottom

- Loaded with sharp cutting knives, the big 10"

auger delivers a steady stream of silage to the

impeller for high capacity output

- New stainless steel auger shroud Auger shroud

cover and sides are made of stainless steel to resist

silage acid and corrosion

- The rugged structural steel tube frame features

a welded construction for extra rigidity

- New motor guard A voluminous cage protects the

ring drive motor from overheating during the non-stop

filling operation

- The 26" high capacity blower with 3 stainless

steel adjustable paddles rotating at 1,225 R.P.M.

for 8,330 feet per minute tip speed

|

|

|

Valmetal

2000 Ring Drive Distributor/Unloaders |

-

Collector ring totally enclosed

- Electrical power is transferred from stationary

to rotating part of the machine by extra-large brushes

and thick copper alloy rings

- Large taper roller bearings inside the housing

support the machine

- Heavy triangular suspension arms to avoid bridging

- Spring-loaded guide wheels to accomodate uneven

silo walls

- Weight is evenly distributed on two large carriage

wheels

- Six replaceable hardened steel blades keep the

silo walls free of frozen materials

- The auger support features a solid oilite ball

bearing, self lubricated, it resists moisture and

contaminants

|

|

|

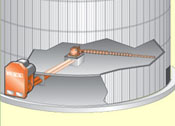

Valmetal

Grain-O-Matic - Borrom Grain Unloader |

- The tapered sweep auger drops feed into the

"positive flow" hopper at the center,

where spinning paddles cycle the material into the

exit auger

- Grain does not just feed down through a center

"cheminey" when you feed out as with some

high-moisture grain unloader

- Grain is less likely to harden near the structure

floor

- 13 H.P. electric motor

- Belt drive 50 and 140 rpm

- Quick action motor mount release

- 10 gauge steel hopper

- Tapered sweep auger shaft and flighting, 3"

increasing to 5"

- Quick action low clearance discharge hatch

- Drive mechanism ratchet type overload protection

|

|

|

|

|